Best Aluminum Hard Anodizing Service in Chennai | Industrial Coating Experts

Enhance the durability and performance of your aluminium components with professional aluminium hard anodizing services in Chennai. IG Quality Industries, Chennai advanced techniques provide superior corrosion resistance, wear protection, and a sleek finish for industrial and commercial applications. Contact us today for reliable and cost-effective solutions!

Chennai’s Trusted Aluminum Hard Anodizing Specialists | Industrial-Grade Coating

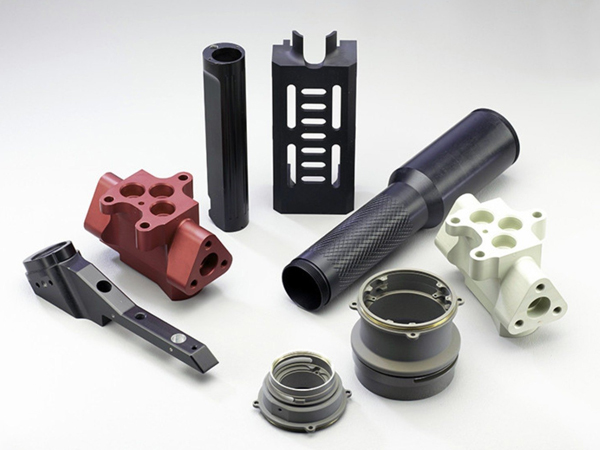

Aluminium hard anodizing is a highly specialized process that enhances the durability, corrosion resistance, and aesthetic appeal of aluminium components. For industries seeking high-performance metal finishing, aluminium hard anodizing services in Chennai offer reliable solutions tailored to various applications, including aerospace, automotive, electronics, and industrial machinery.

- Chennai aluminum hard anodizing

- Hard anodizing service for aluminum in Chennai

- Aluminum anodizing hard service Chennai

- Chennai hard anodizing for aluminum

- Anodizing service aluminum hard Chennai

- Hard aluminum anodizing Chennai service

- Chennai service for hard aluminum anodizing

- Aluminum hard anodizing Chennai service

- Hard anodizing aluminum service Chennai

- Service for aluminum hard anodizing Chennai

- Aluminum surface treatment Chennai

- Metal finishing services Chennai

- Industrial anodizing Chennai

- Corrosion-resistant coating aluminum

- Chennai aluminum coating solutions

- Durable aluminum finishing Chennai

- Anodized aluminum parts Chennai

- Chennai metal plating services

- Aluminum oxide coating Chennai

- Precision anodizing aluminum Chennai

What is Aluminium Hard Anodizing?

Hard anodizing is an electrochemical process that transforms the surface of aluminium into a thick, protective oxide layer. This process not only improves the material’s hardness but also provides superior resistance to wear and corrosion. Unlike standard anodizing, hard anodizing creates a more robust coating, ideal for components subjected to extreme conditions.

In Chennai, a city known for its industrial prowess, aluminium hard anodizing services are in demand among manufacturers requiring precision and long-lasting performance.

PROCESS OF ALUMINIUM ANODISING AT IG QUALITY INDUSTRIES, CHENNAI

- Infrastructure – 1 Natural Anodising Plant & 1 Bright Anodising Plant for profiles up to 6.5 meters.

- Our two Anodising, electro-colouring lines are fully PLC controlled for uniform thickness. We have 3 fully automated sandblasting machines to smoothen the surface & improve the matt finish.

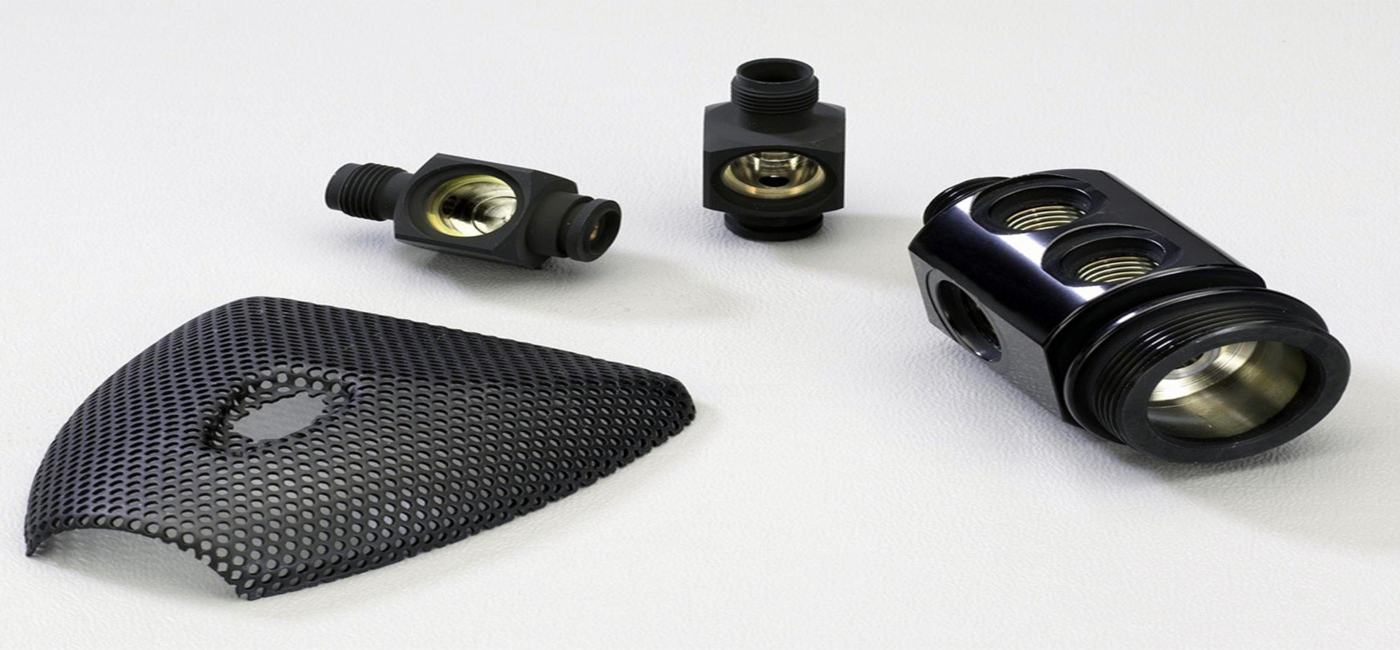

- We provide a range of finishes from natural, glossy, Matt, brush finish, bright finish with coating thicknesses up to 25 microns and colours ranging from silver, bronze, champagne, black, Rose Gold, Sapphire Grey, and SS Finish. Here is the Anodising process that IG Quality Industries follows:

Preparation

The first step in the Anodising process is preparing the aluminum surface. JM Aluminium ensures the surface is clean and free from oils or dirt that may affect the Anodising process, which is done by cleaning the aluminum using a degreasing solution, followed by a thorough rinse.

Anodising

After the preparation stage, the aluminum is immersed in an electrolyte solution, and an electric current is passed through it to cause an oxidation reaction. This reaction creates the oxide layer on the surface of the anodized aluminum. The thickness and colour of the oxide layer can be controlled by adjusting the time and voltage of the Anodising process.

Sealing

Sealing the oxide layer is done by immersing the anodized aluminum in a sealing solution, which helps to close any open pores in the oxide layer, improving the aluminum’s corrosion resistance and making it more durable.

Quality Control

JM Aluminium places great emphasis on quality control throughout the Anodising process. We regularly test the thickness and hardness of the oxide layer to ensure . that it meets the required standards We also inspect the final product for defects or imperfections before it is released to the customer.